- Brake-type low-table disc injection molding machine: an efficient and stable manufacturing solution!

- The present situation and trend of China machine industry

- What do you need to pay attention to before the vertical injection machine is shut down

- The factors that affect the molding of the vertical injection molding machine

- The increase of injection products -- the popularity of injection molding machine is just around the corner.

Contacts:Hanna WANG phone:0769-81929376 Email:waimao005@dg-taifu.com address:Fulong Yangwu Industrial Area, Shipai Town, Dongguan City, Guangdong Provice, China

Characteristic and Price of Rotary Table Injection Molding Machine

source: time:2019-07-16 Click:2810

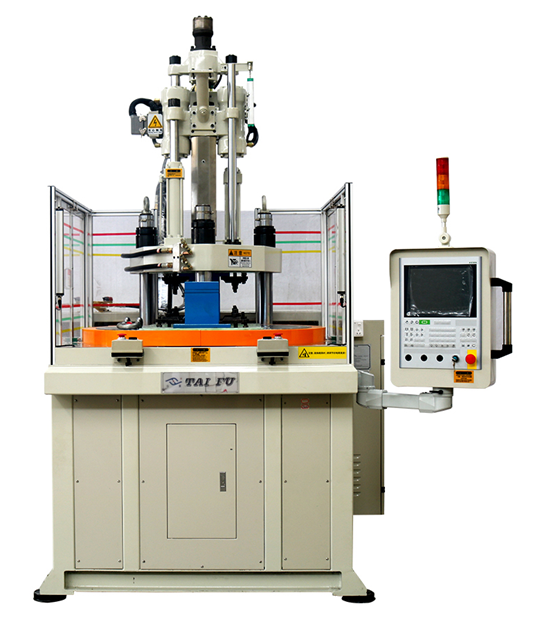

Rotary table injection moulding machine is a very popular type of vertical injection moulding machine.But many people don't know about it. Today Taifu will talk about the price and characteristics of rotary table injection moulding machine.

Under the action of screw, the granular plastic stored in the hopper moves along spiral groove.Because of the combination of external heating and screw shearing, plastics are heated and softened continuously, and finally melted.At the same time, the screw head melt force pushes the screw back.By changing the screw back pressure (working oil backflow resistance), adjusting screw backflow speed and changing plastic flow conditions in screw groove, the purpose of controlling plasticizing properties of plastics is finally achieved.For example, increasing back pressure can improve the homogenization of molten metal and increase melt temperature, which will also affect screw conveying capacity.

When the screw retreats, its actual working length changes, resulting in a decrease in plasticizing capacity.The plastic temperature after melting deviates greatly in the axial direction of the screw, and increases with the increase of injection stroke and screw speed.Therefore, using linear relationship between back pressure and melt temperature, back pressure can be dynamically adjusted according to actual material temperature to compensate for axial temperature difference caused by the shortening of effective length of screw in pre-forming process.Similarly, by adjusting back pressure and rotational speed, it can ensure that there are larger shear force and lower rotational speed under high back pressure, so as to make plasticization uniform.At low back pressure and low speed, the moment of inertia of the screw is very small due to the release of most of melt material pressure in the front of the screw.

At present, the price of rotary table injection moulding machine varies from 100,000 to 400,000, even more than this price, depending on the specific needs of customers to customize.

This article is an original article of Dongguan Taifu Machinery Co., Ltd. (Official Website: www.dg-taifu.com/www.taifu6.com). It shall not be reproduced without permission.

Recommended Products MORE+

-

15 Ton Standard Vertical Injection Molding Machine TFV2-15

-

20 Ton Standard Vertical Injection Molding Machine TFV4-20

-

120 Ton Rotary Vertical Injection Molding Machine TFV4-120R2

-

35 Ton Standard Vertical Injection Molding Machine TFV4-35

-

55 Ton Standard Vertical Injection Molding Machine TFV4-55

-

Motor Rotor

-

Plastic Overmolding

-

Terminals

-

Plastic Accessories

-

SIM Card Tray Holder Slot

Recommended News MORE+

- What are the domestic injection models2018-04-14

- The factors that affect the molding of the vertical injection molding machine2018-04-14

- Noise analysis of horizontal injection molding machine2018-04-14

- Vertical injection molding machine classification, good choice, make entrepreneurship easier.2018-04-14

- The present situation and trend of China machine industry2018-04-14

- Precautions for the hydraulic system operation of the slider injection molding machine2018-04-14

- Pay attention to the vertical injection molding machine and the maintenance of common sense2018-04-14

- Industry market of vertical injection molding machine2018-04-14

- Disc vertical injection molding machine, the best choice of small and medium-sized parts.2018-04-14

- What do you need to pay attention to before the vertical injection machine is shut down2018-04-14